Angebot

Die richtige Beschichtung für Aluminium-Oberflächen

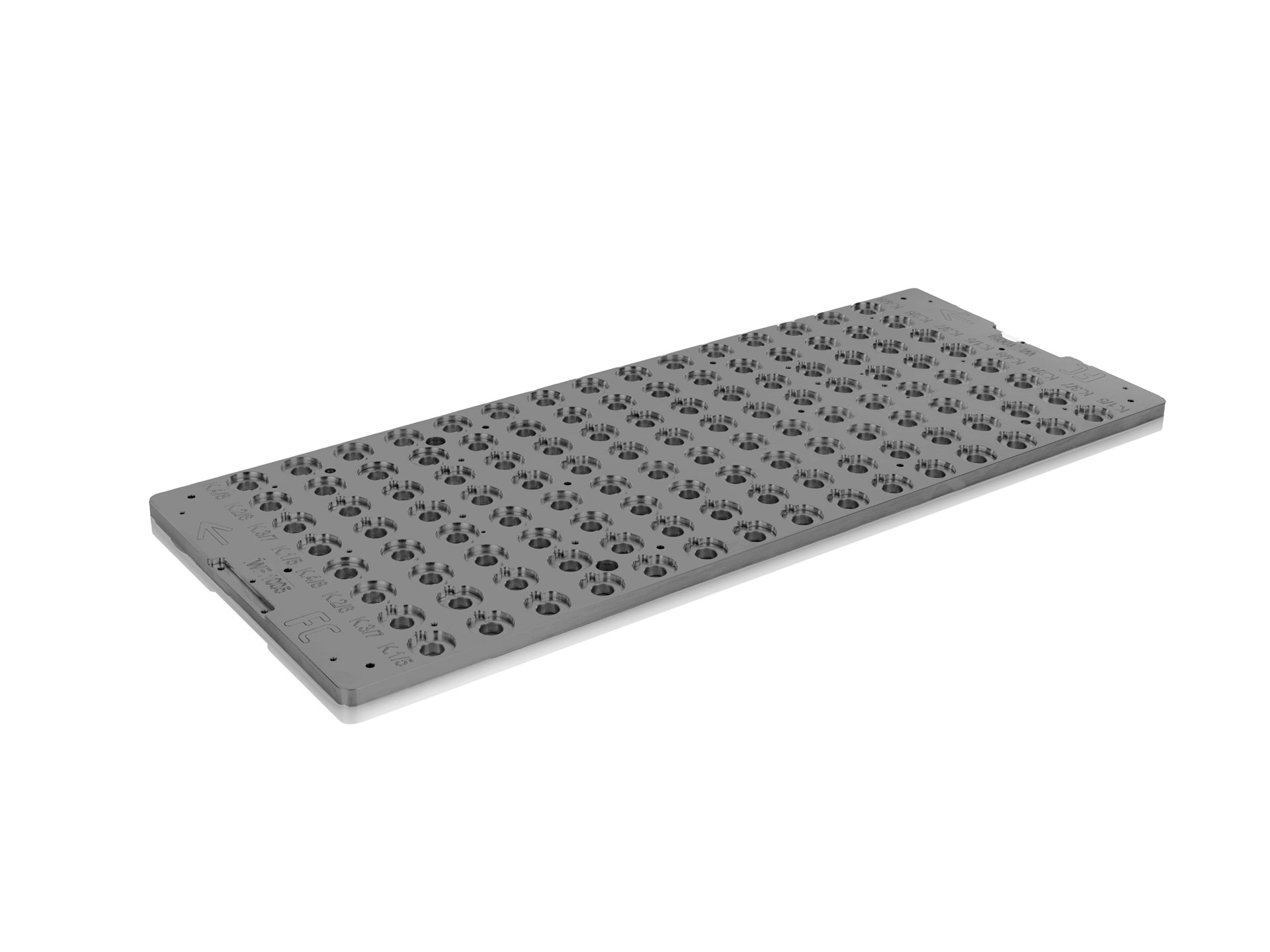

Wir sind Spezialisten für Anodisieren, Hartanodisieren, Hartematalieren und für Haftgrundbeschichten. Mit unseren 6 Marken ELOX, ANOTEC®, ALTEF®, EMATEC®, EMATEF® und ANOBOND® beschichten wir seit 45 Jahren jede Aluminium-Oberfläche – partiell oder komplett – ab 1 mm bis 1,5 m respektiv von 1 g bis 120 kg.

Marken

Beschichtungsverfahren

Anodisieren

Farben

Transparent

Schwarz eingefärbt

ELOX schützt Ihr Aluminiumbauteil vor Witterungseinflüssen und bietet einen grundlegenden Schutz gegenüber mechanischer Beanspruchung.

Beschichtungsverfahren

Hartanodisieren

Farben

Eigenfarbe

Schwarz eingefärbt

Mit ANOTEC® verfügt Ihr Produkt über einen sehr guten Schutz gegen Verschleiss und Korrosion. ANOTEC® eignet sich zudem als einfacher Haftgrund.

Beschichtungsverfahren

Hartanodisieren

Ausführung

Teflon®-Einlagerung

Farben

Eigenfarbe

Schwarz eingefärbt

ALTEF® bietet einen hervorragenden Schutz gegen Verschleiss und Korrosion. Die elektrische Durchschlags- sowie die Kratzfestigkeit sind unerreicht. Die Teflon®-Einlagerung verleiht der Oberfläche zusätzlich Gleiteigenschaften.

Beschichtungsverfahren

Hartematalieren

Farben

Eigenfarbe

EMATEC® verleiht Ihrem Bauteil einen sehr guten Schutz gegen Verschleiss und Korrosion. Der minimale Schichtauftrag erlaubt eine Fertigung auf Endmass.

Beschichtungsverfahren

Hartematalieren

Ausführung

Teflon®-Einlagerung

Farben

Eigenfarbe

EMATEF® verleiht Ihrem Bauteil einen sehr guten Schutz gegen Verschleiss und Korrosion. Die Teflon®-Einlagerung erhöht zusätzlich die Gleit- und Antihafteigenschaften der Oberfläche.

Beschichtungsverfahren

Haftgrundbeschichten

Farben

Eigenfarbe

ANOBOND® ist ein optimaler Haftgrund für Fluorelastomere, die im Anschluss vulkanisiert werden, sowie für Klebstoffe und Lacke.

Beim Beschichten gibt es nur einen Anspruch: Perfektion

Beschichten ist nicht gleich Beschichten. Und ein Versprechen nur dann gut, wenn es eingehalten wird. Dass unser Name und unsere 6 Marken synonym für Perfektion in partiellem und toleranzmasshaltigem Beschichten steht, freut uns ganz besonders. Was es für Sie bedeutet? Sie können sich zurücklehnen, weil Ihr Bauteil in den allerbesten Händen ist.

Altefco – Ihr Standard

Unser Verständnis

Reindenken, vorausdenken, mitdenken

Wenn Sie ein Projekt mit uns realisieren, möchten wir vor allem eins: dass Sie stolz sind auf die Zusammenarbeit, weil sie über die effektive Dienstleistung hinausstrahlt. Damit uns das gelingt, ist die effiziente und effektive Projektbegleitung ein zentrales Thema. Sie beginnt mit einer kompetenten Unterstützung und technischen Beratung in einem frühen Stadium des Projekts und mündet darin, dass Ihre Bauteile Ihren Anforderungen entsprechend optimal beschichtet werden.

Durch die ideale Konstruktion, ausgerichtet auf das bestmögliche Ergebnis, gibt es keine Leerläufe, keine unnötigen Zusatzkosten oder Zeitverluste, die ein wiederholtes Prototyping hervorrufen könnte. Vorteile einer allfälligen partiellen Beschichtung kommen schon in der Phase der Produkteentwicklung zur Sprache und Toleranzen finden rechtzeitig die notwendige Beachtung.

Ihr Nutzen:

Sie sparen Zeit und Geld und profitieren von einem rundum gelungenen Ergebnis.

Reinraum

Auf Wunsch führen wir die Endreinigung und Verpackung im Reinraum durch. Diese Bauteile verlassen unser Haus montagefertig verpackt. Damit beugen wir möglichen Verunreinigungen beim Transport oder bei der Zwischenlagerung vor.

Zertifizierter

Reinraum

ISO 14644-1:

Klasse 8