Wenn es um die Beschichtung von Aluminium-Oberflächen geht, können Sie zurücklehnen. Spätestens jetzt.

Unternehmen

Erste Adresse für beste Qualität

Wir sind ein Unternehmen der eher leiseren Töne, das sich lieber auf den Inhalt als auf laute Parolen konzentriert. Worauf wir stolz sind und was wir auch gerne betonen, ist unsere kompromisslose Qualität. Damit verbunden der Fakt: Wer mit Altefco beschichtet, beschichtet besser. Darauf können Sie sich verlassen. Seit 45 Jahren.

Konfigurator

Finden Sie die passende Beschichtung für Ihr Bauteil

- Funktionsbeschichtung oder Haftgrund?

- Notwendige Eigenschaften?

- Gradierungen der Eigenschaften?

- Die richtige Beschichtung finden

Beim Beschichten gibt es nur einen Anspruch: Perfektion

Beschichten ist nicht gleich Beschichten. Und ein Versprechen nur dann gut, wenn es eingehalten wird. Dass unser Name und unsere 6 Marken synonym für Perfektion in partiellem und schichtdickenhaltigem Beschichten steht, freut uns ganz besonders. Was es für Sie bedeutet? Sie können sich zurücklehnen, weil Ihr Bauteil in den allerbesten Händen ist.

Altefco – Ihr Standard

Ansprechpartner

Gerne für Sie da

Haben Sie eine Frage? Ein Anliegen? Einen Wunsch oder eine Idee, die Sie mit uns besprechen möchten? Wir freuen uns, von Ihnen zu hören und für Sie die richtige Beschichtungslösung zu finden. Zufriedenheit inklusive.

Ihre Anfrage erreicht uns via altefco@altefco.ch

+41 71 973 90 30

Francesco Fini

Mitglied Geschäftsleitung

Leiter Verkauf & Marketing

Josef Würsch

Kundenberater

Stv. Leiter Verkauf

Daniel Ruh

Kundenberater

Gino Kuhn

Kundenberater

Lösungen

Das sagen unsere

Kunden

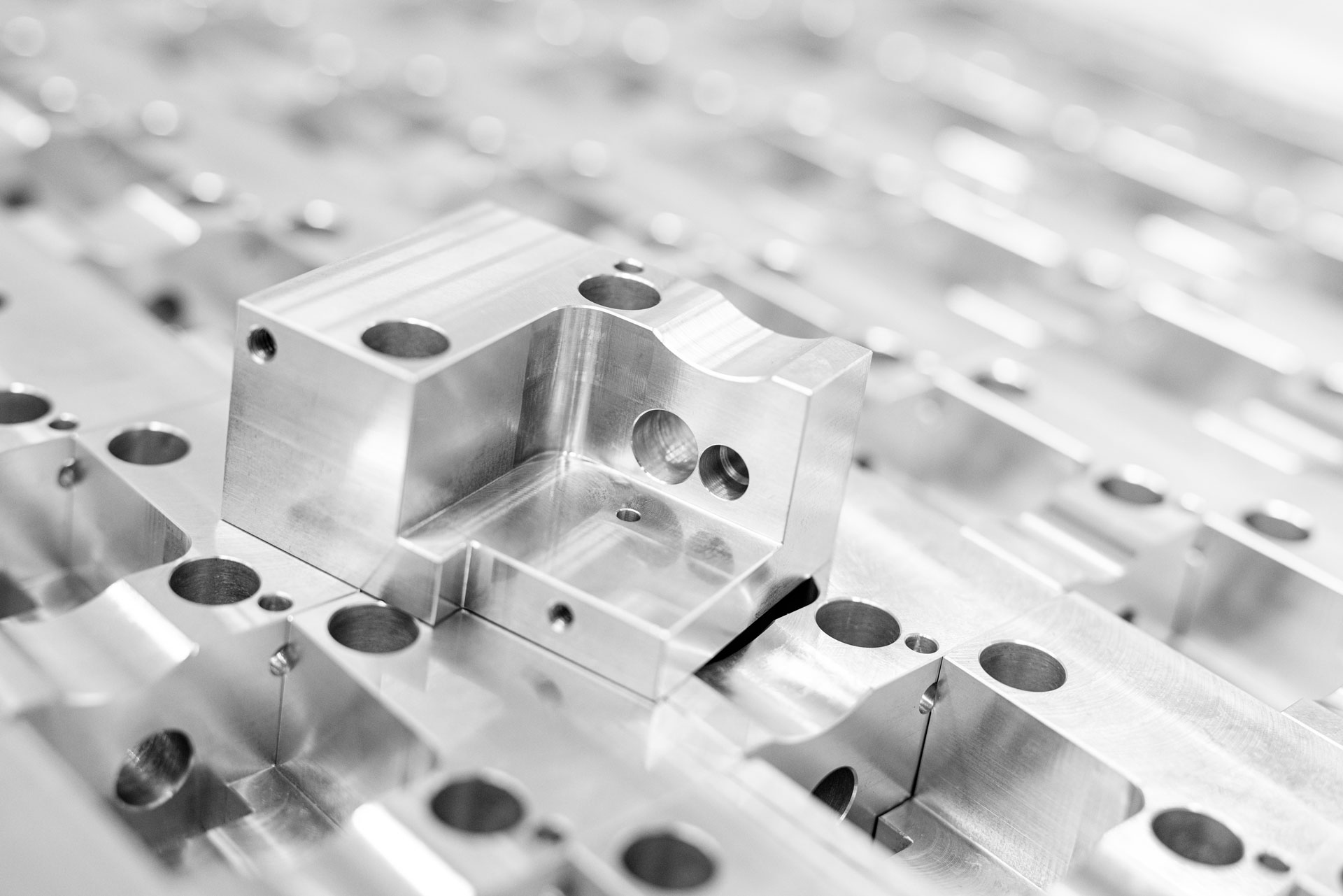

«Mecatyp SA arbeitet als Zulieferer im Bereich der Präzisionstechnik. Unsere spezifischen Anforderungen an die Qualität der Beschichtung sind Härte, Präzision und eine makellos saubere Oberfläche. Wir erwarten von einem Lieferanten Qualität, ein gutes Preis-Leistungs-Verhältnis und Termintreue. Altefco erfüllt dies in allen drei Punkten, deshalb arbeiten wir mit der Firma zusammen und können sie weiterempfehlen.»

Yvan Magnin, Mecatyp SA

An dieser Stelle würden wir zu gerne alle nationalen und internationalen Marken und Unternehmen aufführen, für die wir wirken dürfen. Aus Vertraulichkeitsgründen verzichten wir darauf. Und bedanken uns anstelle dessen herzlich für alle Aufträge.

Altefco-Standard

Ihre Bauteile in den besten Händen

Toleranz- und schichtdickenhaltig beschichtete Bauteile erster Güte